Your location:

Home ->

Products -> Box type substation series

Product overview:

ZGS1 1-12 series prefabricated substations (American type)With small volume, easy installation and maintenance, low noise,low loss, anti-theft, overload capacity, full protection and other characteristics.It is suitable for new residential areas, green belts,parks, stations, hotels, construction sites, airports and other places.

ZGS11-12 series prefabricated substations (American type), suitable for 10kV ring network power supply, dual power supply or terminal power supply systems, is used as substation, metering, compensation control and protection device. This product conforms to the following standards: GB/T17467-2020 "High Voltage/L ow Voltage Prefabricated Substations" and DL T537-2018"6-35kV Box Substation Ordering Technical Conditions".

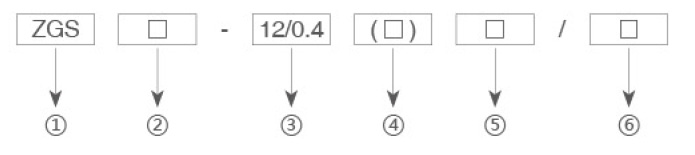

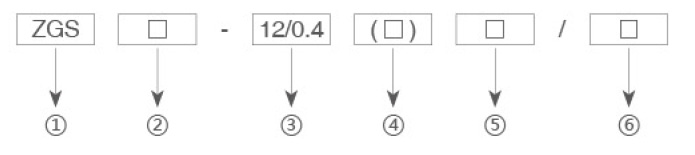

Model and meaning:

①Prefabricated type Substation

②Design number

③Rated voltage

Main switch equipped to high voltage switchgear F-load switch; F.R- Load switch + fuse

Operating mechanism equipped to high voltage switchgear T-spring operating mechanism; S-manual mechanism

⑥(kVA) Rated capacity of transformer

Service condition:

◇Altitude: ≤1000m;

◇Ambient temperature: -35°C~+40°C ;

◇Relative humidity: daily average not more than 95%, monthly average not more than 90%;

◇Relative humidity: daily average not more than 95%, monthly average not more than 90%;

◇Installation place: no fire ,explosion risk or chemical corrosive gas and well-ventilated, the ground dip angle is not more than 3°

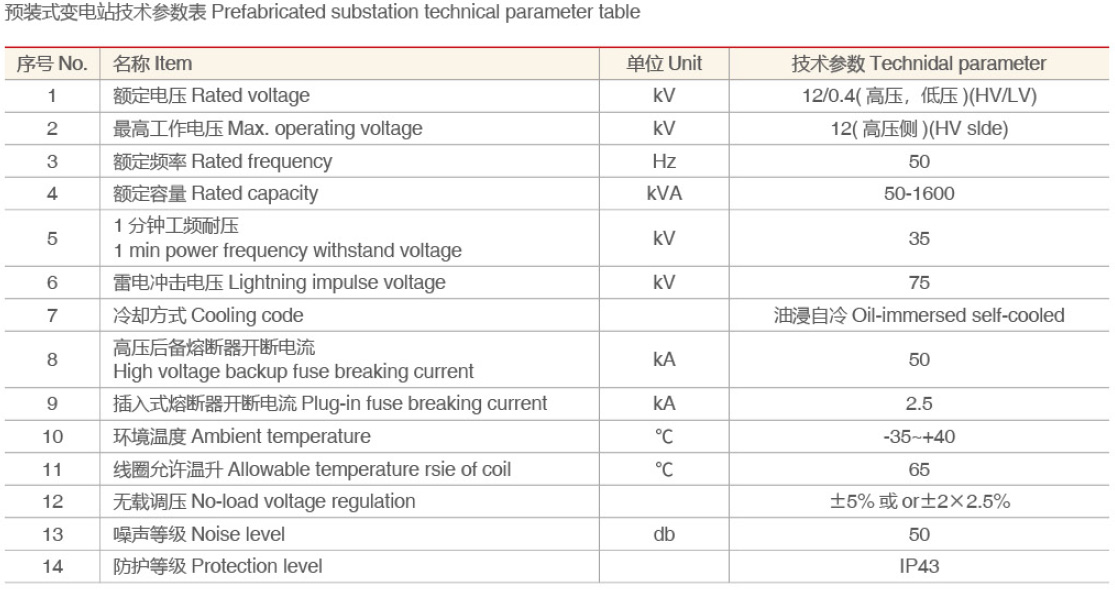

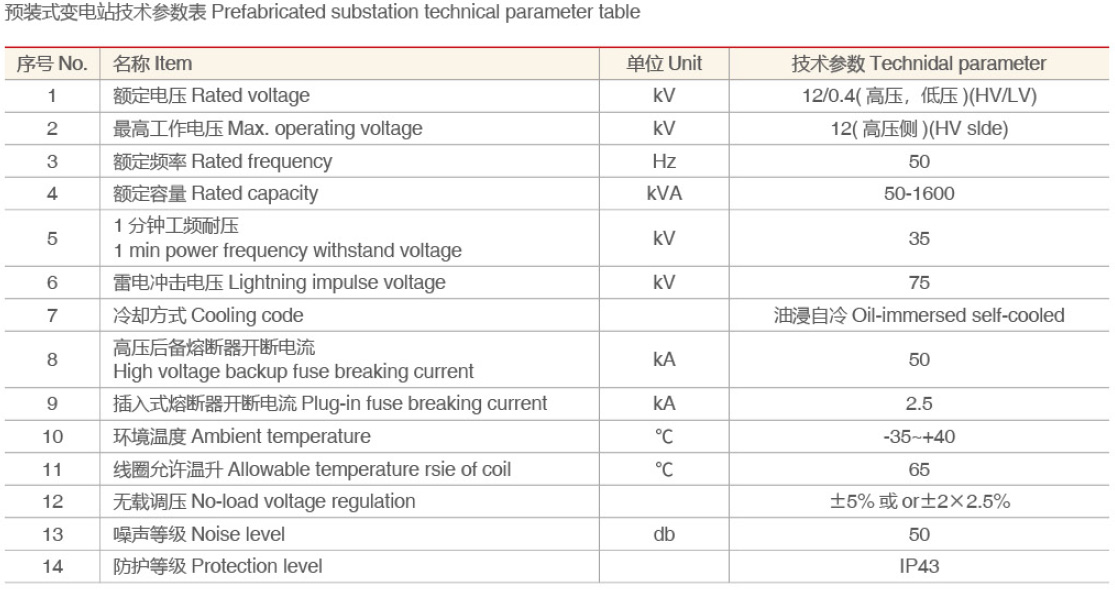

Technical parameters

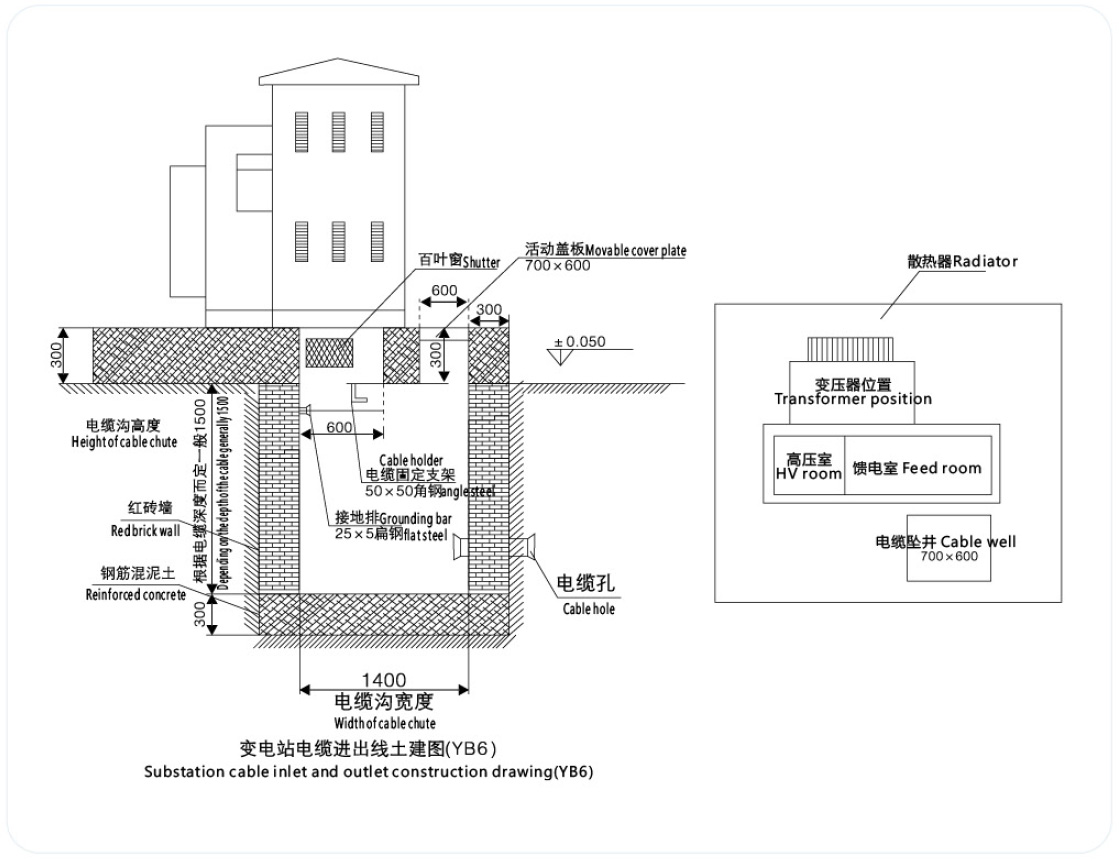

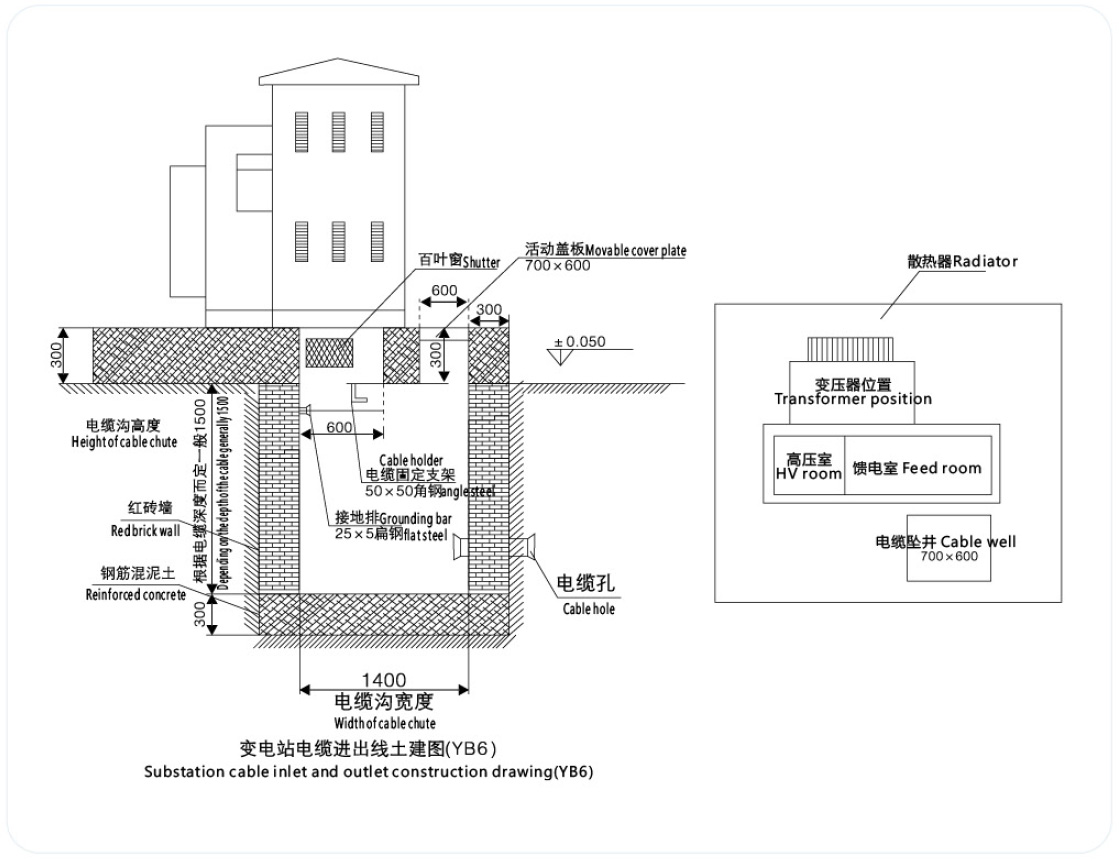

Substation cable inlet and outlet construction drawing:

Substation cable inlet and outlet construction drawing:

Technical requirements:

1. Refer to the actual size of the combination:

2. The surface of the concrete platform shall be at, and the combined substation shall be fixed on the platform by pressing plate fixation;

3. The form of grounding bar and cable fixing bracket can be determined according to the actual situation;

4. Cable fixing frame and grounding bar should be embedded;

5. The location of the inlet and outlet cable hole is determined according to the specific situation;

6. There must be a gap of not less than 1.5m on the front of the switch after installation to facilitate operation.

7. Grounding grid can be made of 12 galvanized round steel or 40X4 galvanized at copper, grounding resistance should meet the requirements of the power department.

ZHEJIANG DANHUA ELECTRIC

ZHEJIANG DANHUA ELECTRIC E-MAIL:123569338@qq.com

E-MAIL:123569338@qq.com TEL:0577-27892288

TEL:0577-27892288

CN

CN